Intellivent Cyclone Dust Collector

Our comprehensive line of standard cyclones cover applications from 300 to 13,000 CFM and operate at high efficiency as a result of optimal centrifugal speeds, from 3,500 to 7,000 FPM. Excellent for high dust load applications with coarse, heavy particulate.

Intellivent cyclone dust collectors (IntelliClone) are mechanical separators that use centrifugal force to remove solid particles from the air stream. Our comprehensive line of standard cyclones cover applications from 300 to 13,000 CFM and operate at high efficiency as a result of optimal centrifugal speeds, from 3,500 to 7,000 FPM.

Special designs may include a longer tapered cone, and higher inlets in the inner helix entrance area to decrease turbulence. To increase efficiency, clean air discharge filter-bag systems can be supplied. We can also provide a variety of dust removal options including cabinets with drawers, bins, and arrangements for 55-gallon drums.

Cyclone Dust Collector Base Options & Assembly

| Features | Benefits |

|

Base Options:

|

|

|

Assembly:

|

|

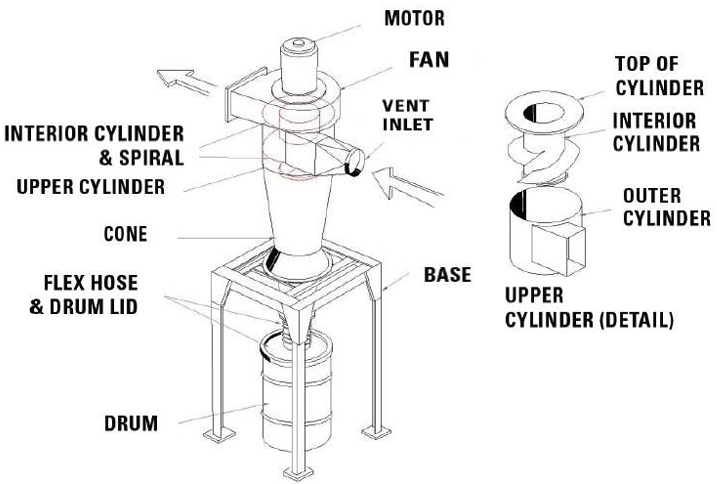

How the Cyclone Dust Collector Works

The dirty air stream enters the unit tangentially and is divided by a spiral type baffle (helix) creating a "spinning" effect to the dirty air stream. Centrifugal force moves heavier solid particles towards the walls of the cyclone, spinning it down to the bottom for discharge. Clean air is directed upward through the inner cylinder (Helix) out of the clean air discharge of the cyclone.

The cyclone discharge system should be sealed when operating under negative airflow; air entering the bottom/discharge of the cyclone results in a reduction in separation efficiency. The cone discharge should have a clearance of at least 4 times the diameter of the discharge, as any restriction may reduce separation efficiency.

Applications

Intellivent cyclones can be used in various applications where there is typically very coarse particles produced in high dust load applications such as woodworking and machining. Intelliclones can also be used for product recovery of medium/fine powders such as paint powders.

Cyclones as primary units may be used alone or with final after-filters depending on where the clean air will be discharged (indoors/outdoors). Cyclones can also be used as a pre-cleaner to reduce the dust loading on downstream air cleaning equipment such as cartridge or bag type dust collector.

We offer manufacturing options that make our cyclones easily adaptable to meet your dust collection needs.

Downloads

Advantaged Operating Characteristics

- Inner Spiral (Helix)

- Wide range of sizes and capacities

- Top Mount Fan for Ease if Installation and Maintenance

- Long Conical Section for Higher Cleaning Efficiency

- After Filter Options

- IVEC® Controls Option Reduces Maintenance

Cost Reduction Guarantee

- Low Up Front Cost per CFM

- Lower Energy Costs by up to 85%

- Significantly Improved Filter Life

- Lower Maintenance Costs

Intellivent™ Dust Collectors Optimize Your Air Cleaning

Establishes downstream air pattern creating higher cleaning efficiency

Improved cleaning efficiency for lighter particulate.

Provide higher cleaning efficiency and cleaner air, generally required for recirculation.

Specifications

Intellivent cyclones are typically selected based on the desired air exchange rate and the resulting CFM required. For applications with a remote blower, cyclones can be selected based on external static pressure loss. When the cyclone is applied as a pre-cleaner with a remote blower system the below table defines the cyclone based on the volume of air and pressure differential across the unit.

| CFM (M3/H) | #19 Cyclone | #20 Cyclone | #24 Cyclone | #30 Cyclone | #36 Cyclone | #44 Cyclone |

| 900 (1,529) | 2.3" (0.57 kPa) | |||||

| 1,000 (1,699) | 2.8" (0.70 kPa) | |||||

| 1,100 (1,869) | 3.4" (0.85 kPa) | |||||

| 1,250 (2,124) | 4.3" (1.10 kPa) | 1.4" (0.35 kPa) | ||||

| 1,500 (2,549) | 1.9" (0.47 kPa) | |||||

|

1,750 (2,973) |

2.7" (0.67 kPa) | |||||

| 2,000 (3,398) | 3.5" (0.87 kPa) | 2.0" (0.5 kPa) | ||||

| 2,250 (3,823) | 4.6" (1.14 kPa) | 2.5" (0.62 kPa) | ||||

| 2,500 (4,248) | 5.6" (1.39 kPa) | 3.1" (0.77 kPa) | ||||

| 3,000 (5,097) | 4.4" (1.10 kPa) | 3.0" (0.75 kPa) | ||||

| 3,500 (5,947) | 6.5" (1.62 kPa) | 4.2" (1.39kPa) | ||||

| 4,000 (6,797) | 5.6" (1.39 kPa) | |||||

|

4,500 (7,646) |

7.2" (1.79 kPa) | 2.7" (0.67 kPa) | ||||

| 5,000 (8,495) | 8.7" (2.16 kPa) | 3.3" (0.82 kPa) | ||||

|

5,500 (9,345) |

4.0" (1.0 kPa) | |||||

| 6,000 (10,194) | 4.7" (1.17 kPa) | |||||

|

6,500 (11,044) |

5.6" (1.39 kPa) | |||||

| 7,000 (11,893) | 6.4" (1.59 kPa) | |||||

| 8,000 (13,592) | 8.5" (2.12 kPa) | 3.2" (0.8 kPa) | ||||

| 9,000 (15,291) | 4.1" (1.02 kPa) | |||||

| 10,000 (16,990) | 5.0" (1.24 kPa) | |||||

| 11,000 (18,689) | 6.0" (1.5 kPa) | |||||

| 12,000 (20,388) | 7.3" (1.82 kPa) | |||||

| 13,000 (22,104) | 8.7" (2.16 kPa) |